Project Overview

Chin Hydro Plant is owned and operated by SMRID. It is located 25km SW of Taber, AB in the side of a coulee on Chin Lakes. The facility was constructed in 1992 and features a 40ft underground structure that houses an 11MW Francis turbine. This can produce enough to power for up to 11,000 homes. Francis turbines are reaction turbines that convert the energy of moving water into rotational motion. Water is moved through SMRID’s state of the art irrigation canal system toward the facility. At maximum volume, water drops through the Intake headgate at 1,105 cubic feet per second (31,290L/s) travelling down a 300m 16 foot internal diameter penstock. At the end of the penstock, water enters a spiral casing and is guided by adjustable vanes, which control the flow direction and speed. Water then impacts the runner blades, causing them to rotate. The rotating runner is connected to the shaft driving the generator, producing power. Water exits axially through the draft tube below the runner into Chin Lakes.

Location

Taber, Alberta, Canada

Objectives

Pronghorn was selected to act as prime contractor on this project starting in October 2024 and concluding in May 2025. The schedule was very critical and had to be met. If the facility was not operating by the end of the allocated shutdown, the Alberta Electric System Operator would charge the owner for lost production. This project was mandatory for the owner as they were required to enhance operational functionality and reduce downtimes/shutdowns. Our scope involved:

Scope

- Installation, terminations, and testing of a 1 kilometre fibre optical line joining the main plant to the intake structure and Drop 18 structure. Civil excavation, hydro-vac, and fiber jetting were utilized. Trenches and pull boxes were backfilled and compacted. Surface reclamation also had to completed for wheatgrass and gravel surfaces.

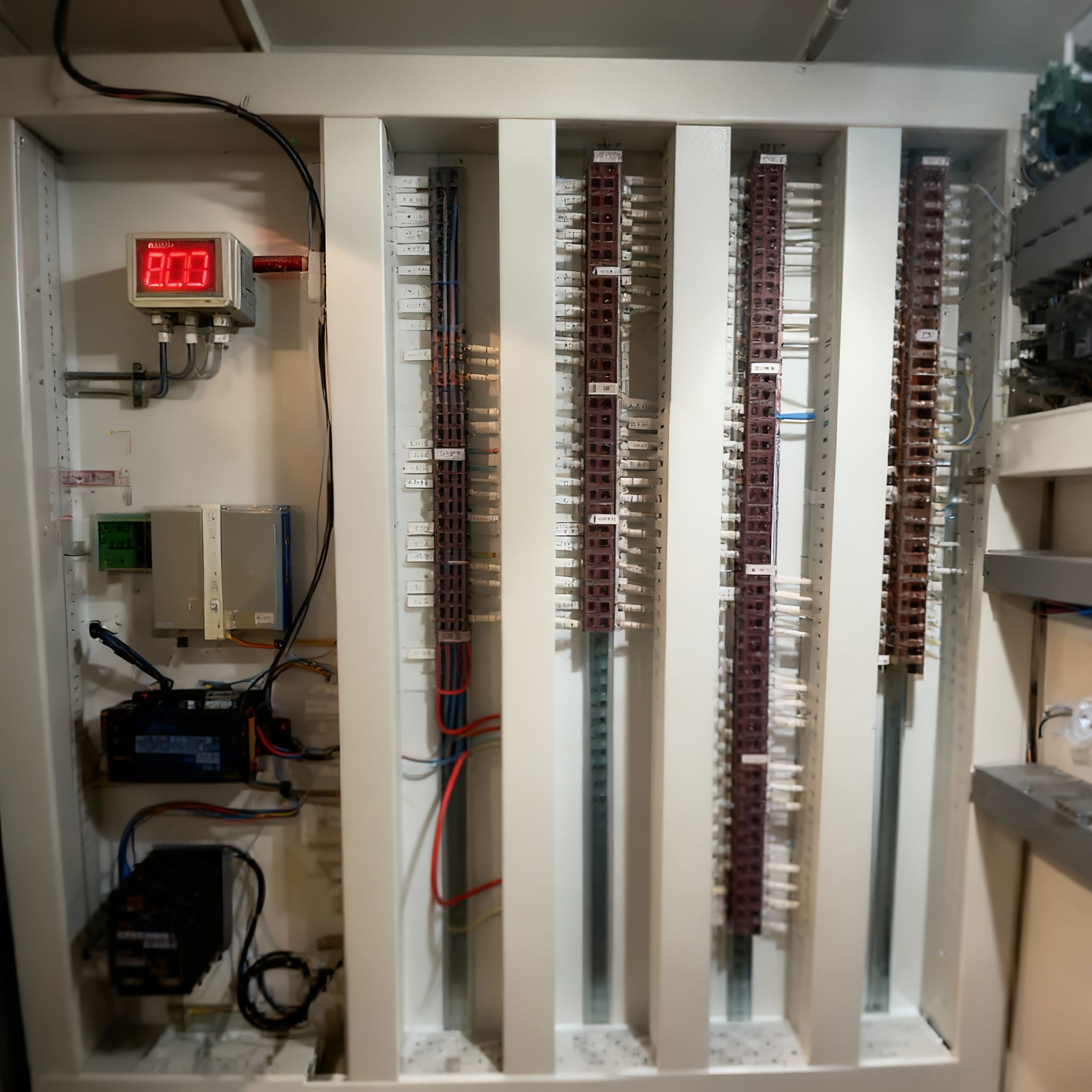

- Extensive demolition of existing control system enclosures, end devices, cabling, tray, and lighting.

- New tray, cabling, and grounding

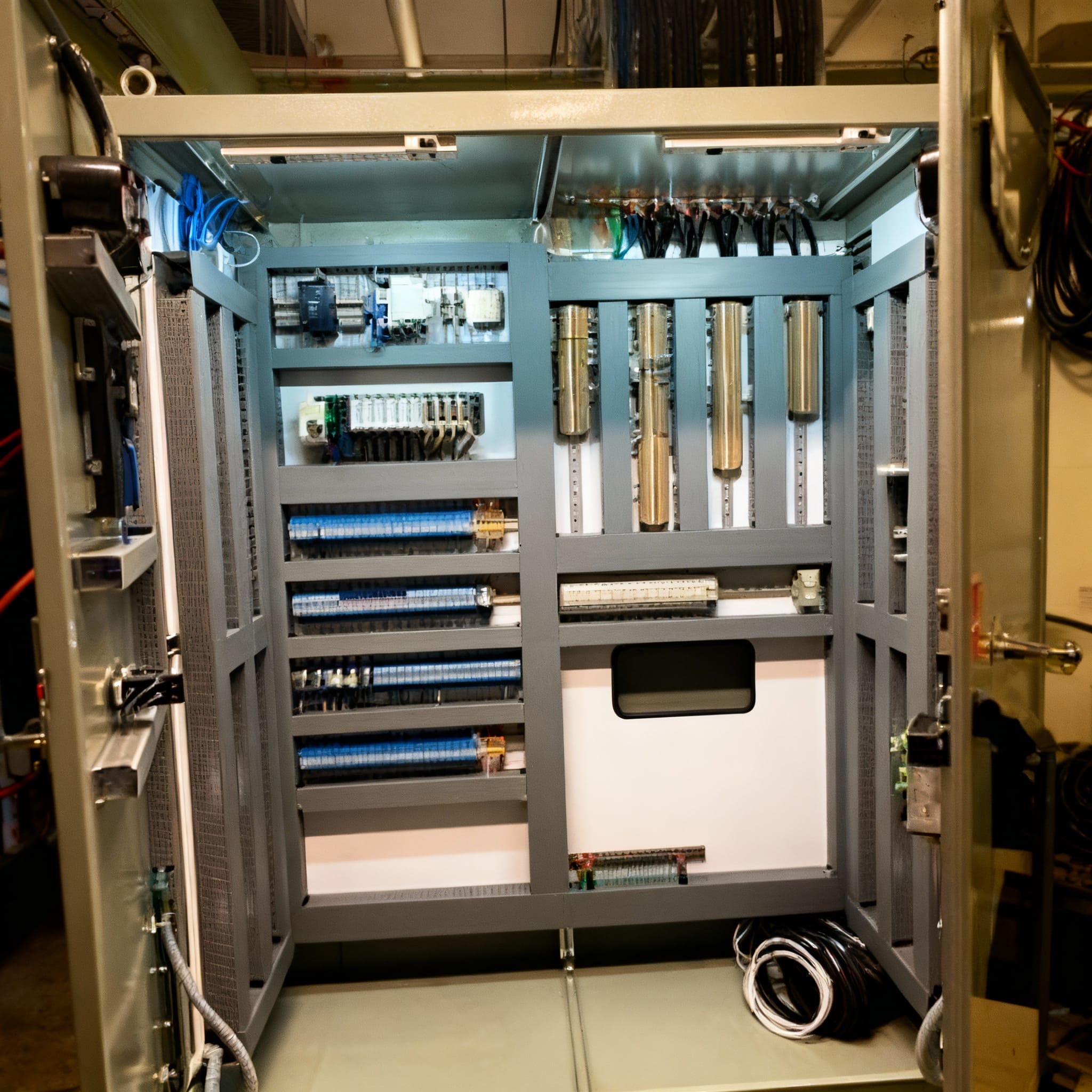

- New excitation controller, protection relay system, digital governor, hydraulic skid, and accumulator skid

- Shipping, crane and rigging, and jack-and-roll

- New data rack, data cabling, end jacks, terminations, and testing

- 40 end devices – water level indication, pressure transmitters, flow meters, proximity switches, RTDs, ESDs, speed sensors

- Main plant PLC

- Intake structure PLC

- 125VDC distribution panel, battery tower, and DC charger

- 24VDC distribution panel, battery tower, and DC charger

- 600VAC distribution

- MCC additions

- Phase line monitoring

- Auto dialer system

- Station drainage upgrades

- Lighting

- Two phases of commissioning